Reducing The Size Of Coarse Line Using Crushing Plant

Improving yield and shape in a crushing plant ScienceDirect

2009年6月1日 By reducing the number of crusher the plant will need less maintenance which will decrease the operating costs The article presents a method to combine crushing plant 2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 2019年5月16日 medium size of rock mass pieces used crushing plant for coarse splitting The next stage to reduce the medium size of rock mass pieces is the use of crushing plant for Computer Simulation Methods for Crushing Process in 2022年4月26日 One such process is a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes(PDF) Optimization Capabilities for

.jpg)

Design and Evaluation of an Expert System in a Crushing

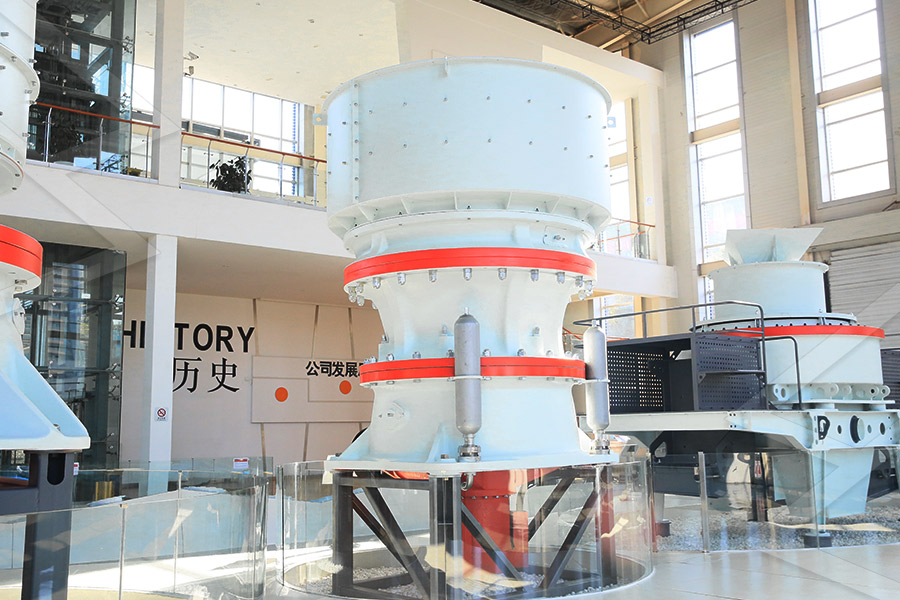

2019年5月27日 Abstract: This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated Size Reduction of Solids Crushing and Grinding Equipment2023年12月1日 All operations in size reduction, both crushing and grinding are of course determined by the feed characteristics of the minerals (rock/ore) moving into the circuit The SIZE REDUCTION BY CRUSHING METHODS By2024年7月26日 In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber The relative amounts of IPB and SPB depends on factors Crushing Principles of Mechanical Crushing 911

Crushing Plant an overview ScienceDirect Topics

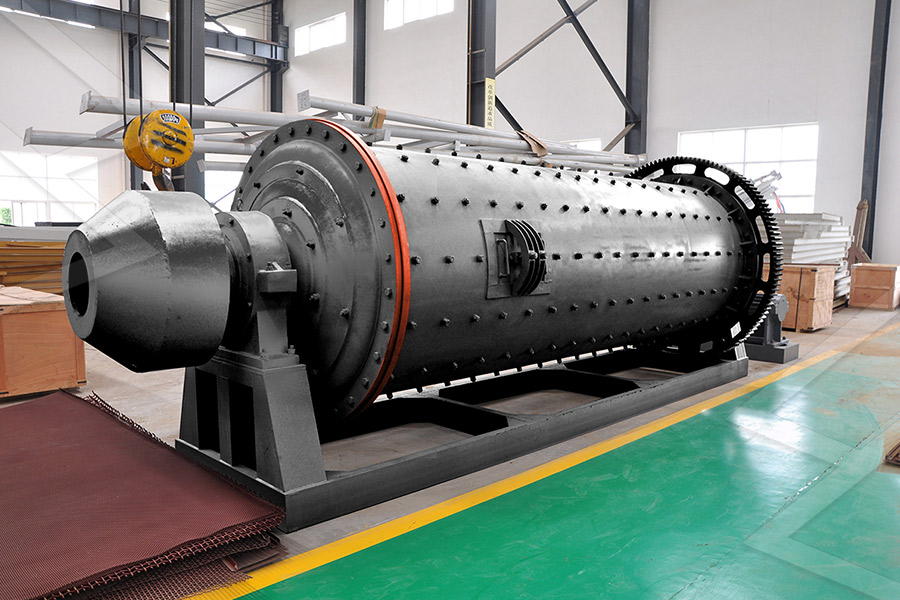

In threestage circuits, ore is reclaimed from ore storage with secondary crushing product typically ranging from 37–50 cm, and tertiary crushing further reducing the ore to ca 05–2 cm in crushing sizes of limestone Reducing The Size Of Coarse Limestone Using Crushing Plant quarry fines minimisation nerc open research archive crushing plant also helps to reduce size of coarse limestone using crushing plantCPM can be multi Size reduction process model s b ⁄ dimensional and shows how the final product depends on variations in machine parameters for a given crushing chamber and feedLayout of a fourstage crushing plant for ballast productiona crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the Optimization Capabilities for Crushing Plants Chalmers

sbm/sbm coarse line using crushing plantmd at main

Contribute to chengxinjia/sbm development by creating an account on GitHubA typical crushing plant consists of size reduction machines (eg, crushers) with intermediate separation machines (eg, screens), transportation equipment (eg, conveyor belts, trucks), Optimization Framework for Crushing Plants Chalmers2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and The Ultimate Guide to Designing an Efficient 2023年2月28日 Tertiary crushing differs from other comminution processes, such as grinding, in that it produces a smaller, finer product size using mechanical force, rather than by using friction or impact Unlike primary and The Complete Guide to Primary Crushing,

.jpg)

Crushing Technologies thyssenkrupp

Each production line will be supplied with a fully mobile crushing plant designed to meet specific customer requirements, each with a throughput capacity of 1800 tph Equipped with a type 2020年12月17日 Mechanized crushing has existed for 150 years Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market Crushing 101 – Different types of crushers for Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive (PDF) Field monitoring and performance 2020年8月25日 for recovery of coarsegrained highdensity mineral prior to further size reduction stage The ore thus prepared in the crushing plant is stored generally in a largevolume Mineral Comminution and Separation Systems EOLSS

.jpg)

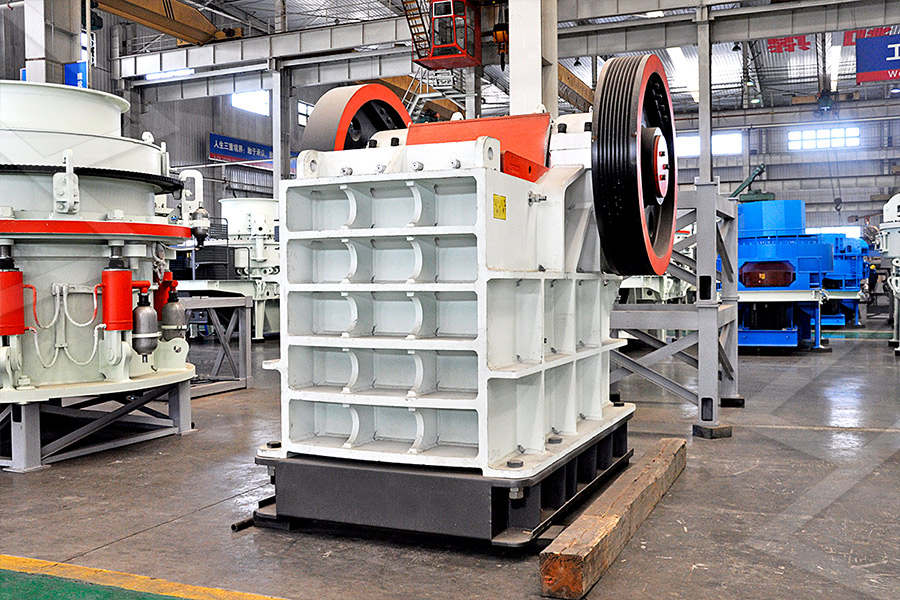

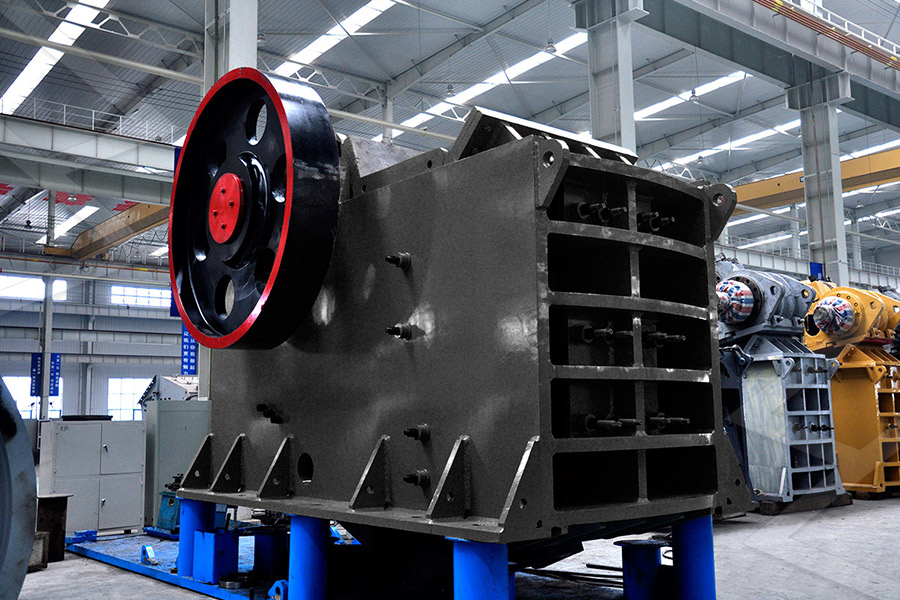

WHAT IS THE CRUSHING PROCESS? MEKA

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is 2021年5月1日 Local exhaust ventilation with reduced energy consumption during bulk materials overloads into receiving cones of coarse crushing plants O A An intense dust emissions Local exhaust ventilation with reduced energy consumption 2024年9月24日 Optimization of a Final Crushing Stage This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value Crushing Principles of Mechanical Crushing 911 2021年5月1日 An intense dust emissions occur when bulk materials are unloaded by wagons into receiving cones of coarse crushing bodies (CCB) The most reliable, but energyintensive way to localize dust Local exhaust ventilation with reduced energy

The largest soybean crushing plant in the world

The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line)2010年8月18日 With adjustment of a crusher's discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) New Trend in Crushing Plant Design and Layout Considerations2021年11月1日 Request PDF Size reduction control in cone crushers Crushing is one of the few remaining industrial processes that is currently being operated using beliefbased manual Size reduction control in cone crushers Request PDFCrushing plant of TDT 33 Storage The end materials are then taken by loaders and stocked on appropriate places until selling Normally fine aggregates are moved directly But coarse aggregates need mixing before stocking because (PDF) AGGREGATE CRUSHING PLANT

Limestone Crushing And SandMaking Plant

2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw 2018年12月26日 For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System Construction, Working and Maintenance of Crushers for 2016年2月29日 The provision of adequate surge storage at the right places in the flow line Any multistage crushing plant will have a “bottleneck” stage, and it is this stage which Crushing Plant: Surge Bins VS Stockpiles 911MetallurgistThe crushing plant is used for both the aggregate industry and the minerals processing industry In case of mineral processing industry, the coarse comminution circuit (crushing plant) is SIMULATIONDRIVEN DEVELOPMENT FOR COARSE

.jpg)

Crushing Plant Flowsheet DesignLayout

2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended 2016年2月10日 diameter before pure gold can be extracted from them The ore usually has to pass various crushing stages, each reducing the ore to a certain size Crushing plant layout is Design of a crushing system that improves the crushing 2024年8月18日 crushing of the aggregates become difficult and results in aggregates which are flaky and elongated Due to the above facts, the aggregates supplied from most of theEffect of Coarse Aggregate Size And Shape on the To determine the effect of effective reduction ratio, the crusher capacity was measured by crushing below 125 mm from a coal particle size of 50–90 mm, with onestage reduction and threestage The flowchart of crushing process with one

(PDF) A Review on the Technology of Size

2020年1月1日 Some of the size reduction operations are crushing, milling, grinding, dicing, etc (SudSushant et al, 2013;Mulla et al, 2016; Kumar and Yedhu Krishnan, 2020) The size reduction creates a new 2020年2月13日 Coarse comminution testwork and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy Understanding Mineral Liberation Contribute to legaojm/m development by creating an account on GitHubm/sbm coarse crushing plantsmd at main legaojm/m crushing sizes of limestone Reducing The Size Of Coarse Limestone Using Crushing Plant quarry fines minimisation nerc open research archive crushing plant also helps to reduce size of coarse limestone using crushing plant

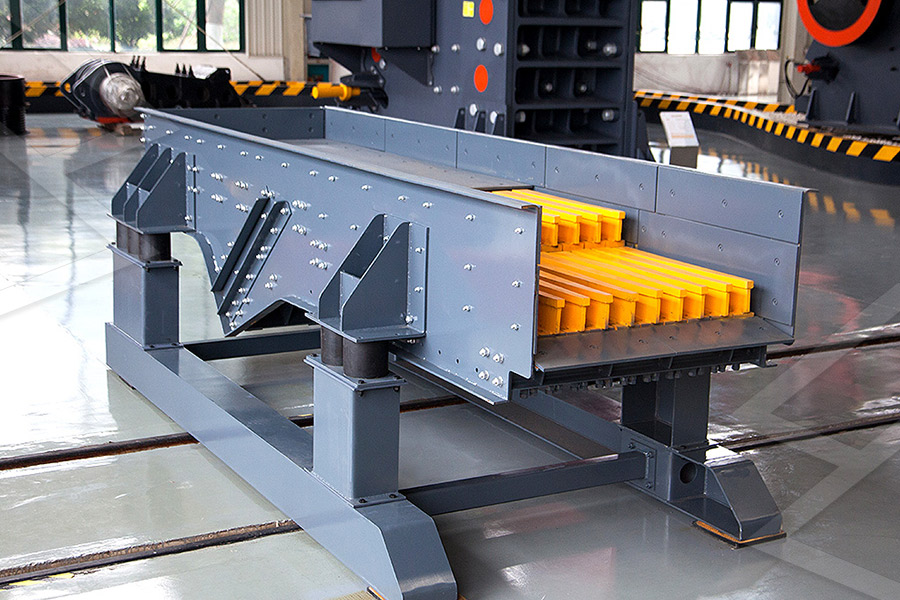

Layout of a fourstage crushing plant for ballast production

CPM can be multi Size reduction process model s b ⁄ dimensional and shows how the final product depends on variations in machine parameters for a given crushing chamber and feeda crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the Optimization Capabilities for Crushing Plants ChalmersContribute to chengxinjia/sbm development by creating an account on GitHubsbm/sbm coarse line using crushing plantmd at mainA typical crushing plant consists of size reduction machines (eg, crushers) with intermediate separation machines (eg, screens), transportation equipment (eg, conveyor belts, trucks), Optimization Framework for Crushing Plants Chalmers

The Ultimate Guide to Designing an Efficient

2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and 2023年2月28日 Tertiary crushing differs from other comminution processes, such as grinding, in that it produces a smaller, finer product size using mechanical force, rather than by using friction or impact Unlike primary and The Complete Guide to Primary Crushing, Each production line will be supplied with a fully mobile crushing plant designed to meet specific customer requirements, each with a throughput capacity of 1800 tph Equipped with a type Crushing Technologies thyssenkrupp 2020年12月17日 Mechanized crushing has existed for 150 years Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market Crushing 101 – Different types of crushers for

.jpg)

(PDF) Field monitoring and performance

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive